Today, was the club day and with my father in Laws birthday today Time was a bit short on the old printer time.

I therefore watched the Fat Dragon Games video on bed levelling, I followed the instructions ( well sort of – I just needed a bit of a confidence boost) it was really useful as it categorically states that turn clockwise to raise and anti clockwise to lower. It also reminded me to level it twice as raising one corner will lower the opposite one.

So I levelled the bed and then tried printing the square floor again as it was one that I had run into issues over. I started printing the raft and noticed that the idler wheel wasn’t turning. I unscrewed it a smidge and it made no difference, so then I screwed it up a smidge and it made no difference. I then, by accident, pushed the arm outwards and the wheel instantly started turning. I let go and, Lo and behold, it stopped turning again. I grabbed a screws and pushed it into the spring and turned it to change the spring length. Still nothing so I shoved another one in and it started turning.

The one that wasn’t turning is the silver one at the front you can see the screws embedded in the springs in the background.

This was how it was starting to look as the wheel began turn…

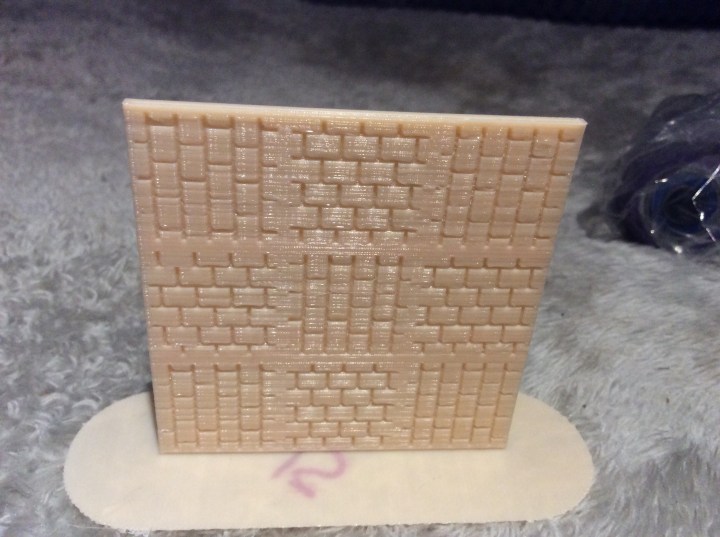

To be honest, the bed is a smidge low, but it is working and is making a nice raft.

I scrubbed and scrubbed the bed but I couldn’t get the shapes off. Once they get covered over with rafts etc then they should eventually disappear.

So as for why the spring was too short… I don’t want to blame anyone in particular, but someone, who shall remain nameless, forgot to add a small item that makes all the difference!

So, once the print on the bed is finished, I will nip out and add it to the extruder spring. I will then be able to remove the springs.

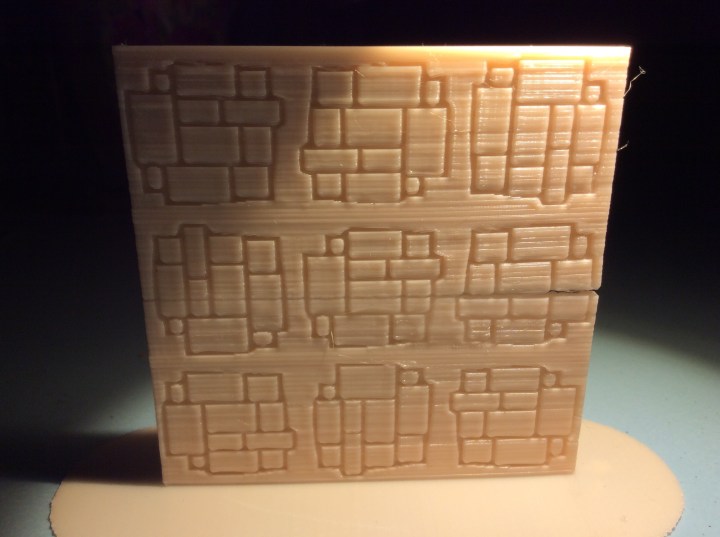

Soooooo after holding my breath for ages…..Two hours and fifteen minutes later we have this…..

PHEW!

I am now printing some rickety platforms…. wish me luck.